• 10 burn-in power units, support up to max 5120 COC

• 4 burn-in cassettes supported by each power unit, each burn-in cassette can be independently controlled

• Burn-in cassette can be loaded offline

• Burn-in temperature 50~150℃ adjustable

• Automatic magazine loading, 20-COC fish bone fixtures, accomoding a total of 640 COC

• The 32-COC fixture is suitable for both burn-in machine and wire bonder

• Dual platform design, save load/unload and pre-heat time

• TEC temperature control(20~100℃) to meet the temperature accuracy and stability

• LlV and spectrum test

• Support the backlight optical power test

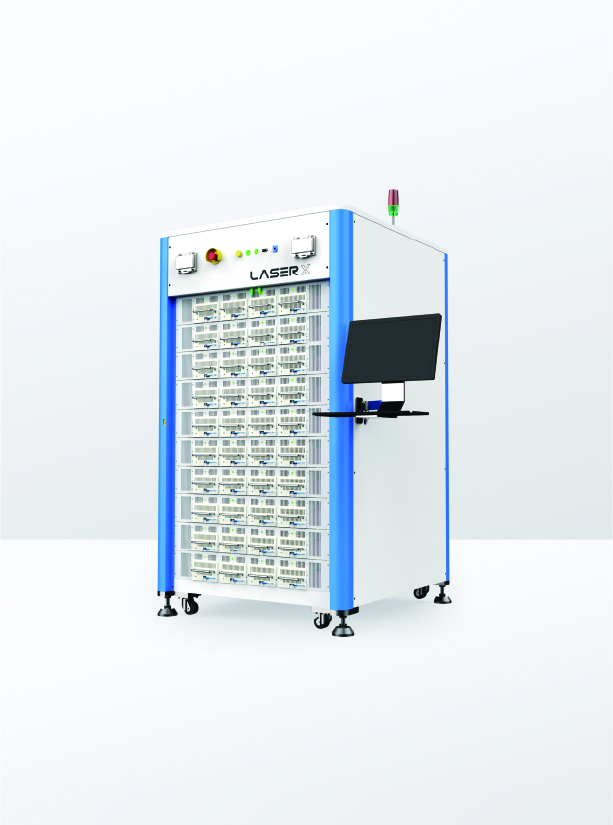

• 20 burn-in power units, support up to 640 COS (might be affected by COS power rating)

• 2 burn-in cassettes supported by each power unit, burn-in cassette can be loaded offline

• Support in-sute optical power monitoring

• Support pump and industrial laser COS

• Fully enclosed design, the test ambient temperature -10~100℃ adjustable

• Support LIV, PER, optical spectrum, and far-field test

• Support pump and industrial laser COS

• Test fixture shared with burn-in machine

• High capacity, support up to 384 channels

• Support for CW and QCW mode operation

• The faulty product can be powered off individually

• In-sute optical power, temperature and voltage monitoring for individual channels

• Optical port reserved for wavelength measurement for chip junction temperature calibration

• Alarm and warning mechanism to ensure the safety operation

• Test LlV, optical spectrum, far field, polarization extinction ratio

• Automatic OCR chip/substrate lD for data binding

• Load/unload flexibly configured with waffle pack, Gel-pack and B/l fixture

• Dual test platforms for parallel test to increase UPH significantly

• Development is in progress to integrate AOl feature for defect detection

Shenzhen Headquarters:Building 3, Yufengda Industrial Park, Guangming District, Shenzhen City, Guangdong Province, China

Shenzhen Headquarters:Building 3, Yufengda Industrial Park, Guangming District, Shenzhen City, Guangdong Province, China

Reception Service Number:0755-23019639

Reception Service Number:0755-23019639

Consultation Email:hongbin.ding@laserx.net & laserx.xs@laserx.net

Consultation Email:hongbin.ding@laserx.net & laserx.xs@laserx.net

About LaserxCompany ProfileDevelopment HistoryCompany CultureHonor and Qualification

ProductsBurn-in And TesterOptical AlignmentSemiconductor PackagingChip TesterHigh precision linear and goniometer slide

SolutionSmart Factory SolutionPhotonic Assembly and AlignmentIndustrial Laser Burn-in And TesterAdvanced packaging

Copyright © 2017-2026 LASER X Technology (Shenzhen) Co., Ltd. 粤ICP备2020137519号-1